Flexibility and Innovation

with long Tradition

Helmut Brüninghaus GmbH & Co. KG has been founded in 1909 as a manufacturer of saddles for motorcycles and bicycles. Since 1954 we are specialist in manufacturing crown corks.

Customer service, flexibility, quality awareness, innovation and experience have made us one of the leading manufacturers in Europe.

„Brüninghaus is a synonym for high quality and excellent service – just two reasons of many for the successful, long-term cooperation with our customers.“

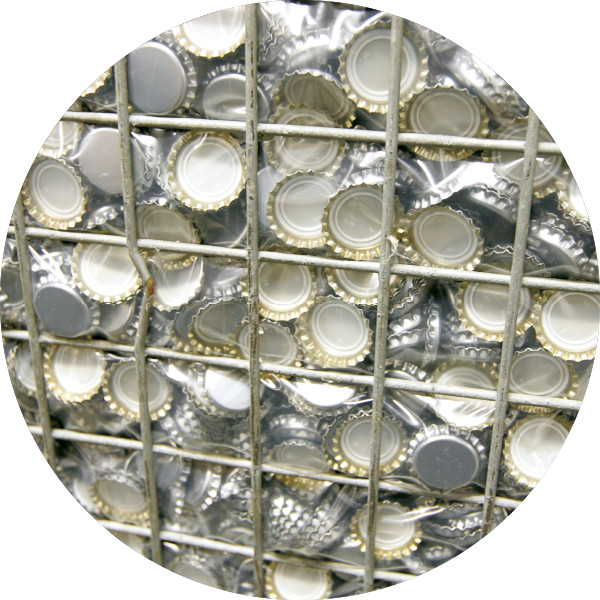

High Precision with 21 Flutes

The quality of the raw material is decisive for the quality of the final product.

Especially the base material tin plate in many different specifications or chromium-plated steel (TFS) has a main impact on quality. Therefore our philosophy is to source only at well reputed, certified suppliers.

Production Process

Coating: Protection against external damages

In the first step, the metal sheets are getting lacquered on both sides. The layer of coating gives resistance to corrosion and is suitable for printing, deep-drawing and is recyclable.

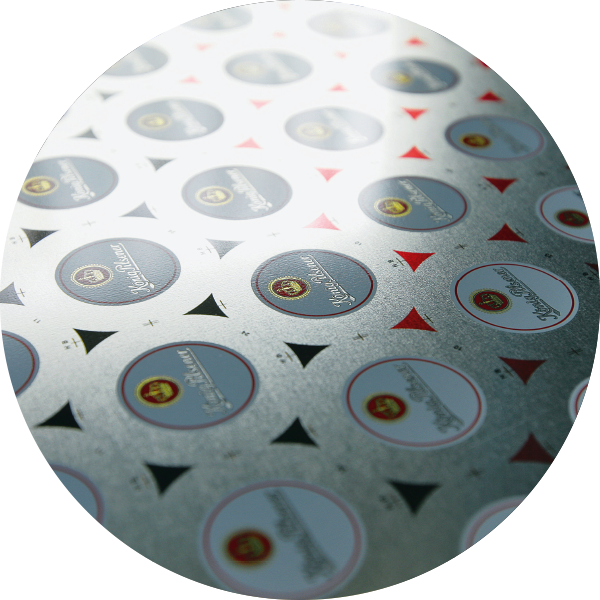

Printing: From design to individual brand presentation

The printing of the lacquered metal sheets is the most challenging process during production.

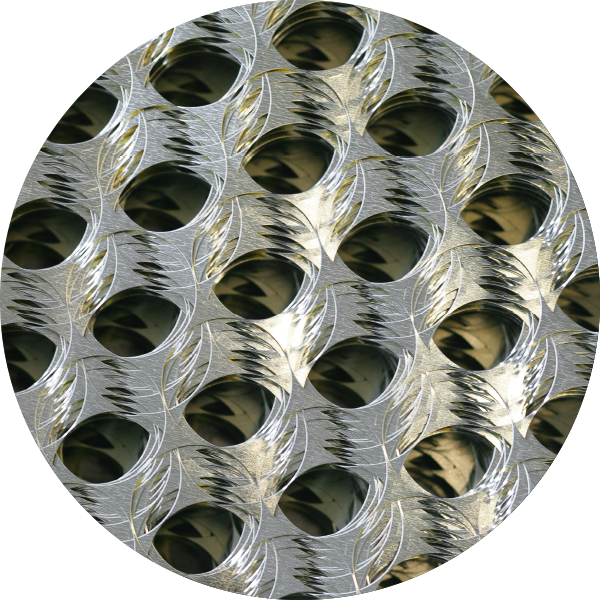

Shaping: Punching and Lining

During the process of punching and lining the crown cork is getting its typical shape with 21 flutes.

The crown cork: small advertising medium with great effect

The crown cork is an essential part of beverage advertising. The easy fast opening of the bottle and the pouring drink symbolise freshness and enjoyment. The printed crown cork with its own unique design is a powerful performance of the brand. Like the shaped Coca-Cola bottle the crown closure has a great image value today through its consistent form. Its technical advantages, such as fast fitting, easy handling, sealing capacity, price reliability and tamper evidence is completed by its perfect advertising possibilities.

When buying bottles , the customer notices the crown cork at first sight, especially in crates. The almost unlimited possibilities in terms of design enable the identity of the brand to be presented with maximum effectiveness on a small advertising area.

Promotions

The inner side of the crown cork is suitable as further advertising space: it can be printed individually with winner or collecting pictures and ink-jet or laser codes can be applied.

Also embossed crowns are available. Similar to the embossed glass bottle, the profiled surface adds a premium product touch to the bottles’ content. The closure thus becomes a cult object.

Twist-off-crowns

The components utilized for the manufacturing of Twist-Off-crowns are different, especially lacquer, liner and metal hardness. Due to the softer metal, the thread of the bottle neck is embossing itself into the crown. Non-PVC Compound and lacquer assist in easy removal of the crown. The twist-off-crown is only suitable on one-way bottles as the bottle thread can be damaged when opening the bottle.

Quality

In addition to the electronic Quality Control Systems we are carrying out tests on the incoming raw materials and the final products in our own laboratory. By the challenging certification according to FSSC 22000 which also covers all requested HACCP criteria and ISO 9001 we fulfill every demand on product quality and safety. The laboratory tests are carried out according to the STLB and MEBAK.

Our Code of Conduct and Corporate Culture you can find here.

Packaging

Cardboard boxes

on pallets

Pallet dimensions: 800 x 1200 or 1000 x 1200 mm

Content: 10,000 pieces

Weight: approx. 23 kg

Dimension cardboard box: 39 x 29 x 46.2 cm

Octabins

fillable with 370,000 pcs

Pallet dimensions: 1000 x 1200 mm

Content: 370,000 pcs

Weight: 830 kg

Height: 1.80 m

Silotainers

stackable

Pallet dimensions: 1000 x 1200 mm

Content: 330,000 pcs

Weight: 855 kg

Height: 1.70 m

Protection of Environment and Ressources

With our state of the art manufacturing-equipment for Crown Caps we are focussed on our responsibility for global health and environment. Our site has been basically restored according to the newest energy standards in 2010/2011. 2015 we installed a new lacquering line with gas savings of about 50 %. And of course we are certified according to Energy Management Standard ISO 50001 and committed us for further savings in energy and ressources. The metal we are using is certified as “Metal recycles forever” and is part of our sustainability and ressources saving program.

Investing in our Future

In December 2017, the project „Resource Efficiency Consulting“ was launched in our company, under which we receive funding from the ERDF.

In the production of crown corks waste heat accumulates in various processes. The target of the project is to identify the sources of waste heat, to quantify their volume and to identify possibilities for waste heat utilization.