Services

Branding & Promotion

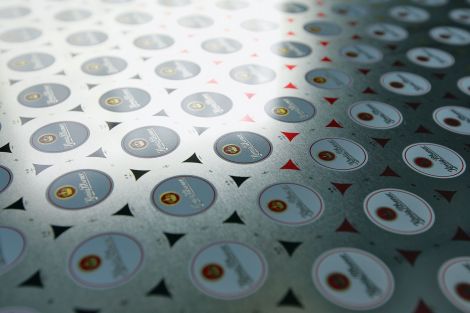

Outside / external branding – small advertising medium, big impact

Strong brands and strong taste: with Brüninghaus' high-quality crown corks, you can rely on absolute sealing performance and effective branding. With the utmost precision and state-of-the art technology, we ensure that your logo and corporate identity colours are applied to each crown cork in a distinctive and perfect manner. Continuous monitoring and fine-tuning of the printing processes, as well as automated camera-controlled quality control, guarantee brilliant colour fidelity and first-class quality – for a convincing first impression that strengthens your brand image. Always included: easy handling for a really great look, taste and feel.

Sales promotion on the inner side – crown cork promotions & competitions

Games or collection campaigns: Crown cork promotions and games are extremely popular with consumers and fans: various codes or text messages on the inside of the crown cork provide excitement and interaction – while also strengthening brand loyalty. To ensure your promotional campaign is a success from the start, we implement your ideas in offset printing as required, and for greater personalization in inkjet or laser printing. No matter how unusual or individual your promotion idea may be, with precision and reliability, we transform your crown corks to the ideal platform for competitions and collection campaigns.

Production

From idea to effective advertising crown cork – everything from a single source

With our modern machinery, we implement your ideas and requirements in four consecutive production steps. With decades of experience, we are continuously developing these processes – and provide you with reliable support in ensuring the quality of your products.

Benefits of the process

- ensuring our delivery capability

- efficient processes

- complex and individual designs

- sustainable packaging and logistic solutions

Your benefits

- personal contact

- short and reliable delivery time

- all in one-solutions

- expert advice

Manufacturing Steps

In the first production step, we cut sheet metal plates from steel coils. A modern cutting line ensures fast, precise, efficient and reproducible results:

We always stock up sufficient quantities of chrome-plated and tin-plated materials in various specifications in our warehouses. This makes us independent of supplier shortages and ensures our delivery capability.

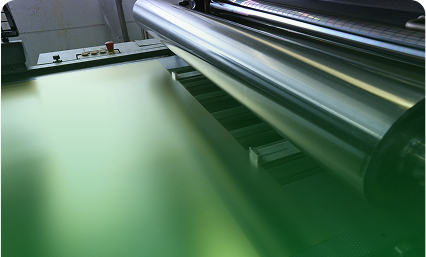

After cutting, the next step in the process is coating.

In a first coating pass, we apply a coating to both sides of the sheet metal panels in a tandem coating machine:

Adhesive laquer on the inside: The interior coating increases the crown corks resistance to corrosion. By reheating the coating during the subsequent insertion process, the inner coating also ensures that the liner adheres properly.

Outer base coat: The outer coating gives the crown cork its basic colour: gold, silver or white across the entire surface. It acts as a carrier medium for subsequent printing and also protects against corrosion.

Outer protective coat: To protect the print image, haptic and aesthetics from scratches and other damage during later use, we apply an overprint varnish to the surfaces after printing. A centralized coating supply ensures consistently high quality and makes our teams' work easier.

Printing individual designs onto the lacquered metal sheets is the most demanding manufacturing step producing crown corks. The offset printing is used in our production process. Print files are adapted in-house and prepared for printing.

We first review the drafts for branding and individual promotional campaigns. This allows us to rule out any potential technical problems with transferring your marketing ideas to the crown cork before the printing process begins.

The following must be considered:

- size of characters or fonts to prevent them from blurring

- adopted designs to meet the cap size

- a printed corongation may result in increased abrasion during the subsequent filling process

During the punching and lining process the crown corks receive their typical, uniformly 21-point shape and the sealing compound.

During the punching process, the laquered and printed metal sheet are cut and deep-drawn simultaneously. The crown cork now has its typical shape with 21 prongs.

From the punching machine, the so-called empty sleeves continue to the insertion machines. Here, the crown cork receives its polyethylene plastic seal. Material properties and different sealing profiles are selected according to customer-specific requirements.

- This process is followed immediately by a 100 % final inspection. Electronic camera systems check the inside and outside of the crown cork for quality-related parameters.

Directly after inspection, the crown corks are electronically counted and filled into the desired container.